Click on featured sections below

Firearms and Equipment Recommendations

Spray Paint Projects

Cerakote Refinishing

Robar's Refinishing Services

Sig 556R Test & Evaluation

Extended 2 year AK test

Disassembly tips on AKs

4-11-2022 Ongoing test with Sig Romeo optic

Unintended yet perfect occurence for abuse test: Romeo optic that was issued on Sig P320RXP

Slide dropped as shown above and impacted top left corner of rear sight. Romeo glass cracked.

Red dot still visible regardless of fractured glass. Will run more rounds and see how it holds up.

7-10-2022 Ongoing test with Sig Romeo optic

About 100rds fired since glass cracked; some glass flaked off, and now red dot doesn't stay on.

But most important of all; having cowitness iron sights still allows effective use of this handgun.

8-05-2022 Ongoing test with Sig Romeo optic

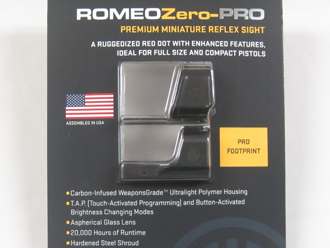

Replaced cracked unit with Zero-Pro (polymer body with steel shroud). Will begin usage tests.

Original issued Sig Romeo with cracked lens will be sent up with request to repair or replace.

Continuing report on Daniel Defense M4V1LW

Was it necessary to dunk the rifle and electronics in water? Not really.

Is this what people want to see? Absolutely!

This rifle has been in use for 3 years. Predominantly run with Tula and Wolf steel-cased ammo,

it has been fired in 500~600 round cycles minimum without cleaning and gone through two

Shooting Sports Fairs (which means weekends of constant firing with high round count).

It has also been painted about 2 years ago, and now has had 3,000+ rounds through it.

Still dirty in a 500+ round cycle, December 2013: into the water it goes!!

The Daniel Defense M4 was left submerged in the water about 5 minutes.

Bubbles and oil emerged from the rifle as every crevice of rifle filled with water.

To add to the soaking appeal, rifle was dunked with the Trijicon RMR and Surefire X300.

It was then brought out, drained and fired - no suprise, it operated just fine.

The Trijicon RMR optic and Surefire X300 light also worked fine.

After firing, water pooled out of mag and stock, and emergency parts bag was found to be soaked.

(every rifle should be setup with spare parts!) No big deal - in fact, it's awesome! This is the level of

minimal torture of modern military firearms that every firearms owner should feel confident about!

Not everyone would like to do this to their rifles, but know that they should all handle a bit of water.

Recognize however that quality electronics is of extreme importance.

Would you want to risk using anything inferior on your defensive firearms?

Protective factory finishes on your defensive handgun

A common question especially in tropical climates: "in the worst conditions; which finish holds up the best?"

Melonite (Springfield XD, Smith & Wesson M&P) has been claimed to be a good finish but it took some years

before becoming a better finish. Early XDs (2002) and M&Ps (2005) that claimed Melonite finish still rusted.

From what has been seen with past inventory, if not kept oiled, just one handling session could cause rust.

With consumer's guns - if circumstances led to not being able to oil and maintain firearms, it will be apparent.

Many claim "my gun don't rust" - try a mild 'natural disaster' test and they often will. Sig's Nitron finish rusts.

Melonite variations 2009/2010 (as on current S&W pistols) seem to be vastly improved from the early versions.

Glock's Tennifer treatment (unchanged from 1983) still has the longest proven track record in adverse conditions.

HK's Hostile Environment finish (1993) also has a long-running successful track record in corrosion resistance.

Contrary to what many articles claim, matte or bead blasted stainless for various firearms is the worst,

as brown of rust is more visible and freckling is bound to happen - those who use guns hard will see it.

Since I utilize a large number of handguns for teaching and personal use; if it can rust, I get it refinished with

special rust-resistant coatings. Operating a shop & teaching each week with many (20+) class guns requires it.

Rain. Salt rain. Seen here on many class guns, water all over and inside the handguns. If not protected; yikes!

How many would even think of letting their guns get rained on? This is why HK's Hostile Environment finish

and Glock's Tennifer are hands down the best in the industry. Why don't more companies follow their lead?

Slowly, other manufacturers are releasing guns that have coatings to resist some of the rusting possibilities.

Melonite finishes just may prove itself over the next few years. Good track record still requires years of proof.

Guns in use: Foreground: HK P2000 with their HE finish. Background: Sig P228 with Robar's NP3 finish.

HK and Glock finishes are factory standard! Robar's NP3 is satin gray nickel-teflon; I'd say well worth the cost.

NP3 satin gray nickel-teflon finish is now applied by Wright Arrnory: wrightarmory.com

If it doesn't come with a good enough factory rust-resistant finish, or have a worthy aftermarket finish

already on the gun, I send the firearm(s) out ASAP after "break-in" to get protective coatings applied.

It is a great relief when having to deal with bad weather, constant usage situations, and cleaning/maintenance.

Silhouette Range not crowded at all... due to lots of rain. Small waterfalls poured down the ridges of Koko Head.

On this very rainy Sunday in December... It dumped so much rain, ponds/lakes formed. Perfect for salt rain test...

I hear so many people brag about their shooting ability and run away from the chance to shoot in the rain.

Oh, and how so many talk up their favorite gun(s) and the high price they paid? Ready to put your guns

and your nerves to the test? Ready to detail strip that complex, 50 to 60 parts count reputedly 'superior' gun

and magazines to prevent rusting and seizing parts of that beloved $1,000+ 'fair-weather-only' defense gun?

1911 directly above in picture: classic example most would never even dare think about: use your 1911 in the rain.

Even deeply textured G10 grip panels that seemed secure when dry become slippery in this onslaught of rain.

Slide serrations that looked ok in dry conditions offer no grip and nearly impossible to run to the rear while wet.

Many manufacturers seem to have lost sight of what matters in fighting handguns - slippery means no control.

The 1911, Sig, Berettas in pictures needed to be cleaned thoroughly and oiled extremely well. Even though this

Sig had Robar Tecnologies' nickel-teflon NP3 satin gray finish, it still required some attention in getting oil onto

springs that aren't able to be NP3 finished. HK P30 was less of a concern with its factory Hostile Environment

finish although there are many small internal parts that also should get a thorough oil treatment. These Beretta

92s shown above have blued barrels that would rust immediately so grip screws+washers, parts under the grips

had to be cleaned and oiled just the same as the 1911s and Sigs. Oil I use is non-carinogenic mineral Ballistol.

It emulsifies with water and effectively gets to all the steel parts inside hard to reach areas w/o detail stripping.

Glock is clearly a winning gun; the factory Tennifer finish has been utilized since 1983, and is the best example

of a defensive handgun that no one worries about serious usage - even in the rain. Minimal parts inside the gun.

Glock's Rough Textured Frame had good grip in this soaking wet condition. Pebbled grip on M&P did not.

Glock's Gen3 RTF curved slide serrations were a step in a positive direction and improved gripping ability over their

standard vertical serrations. Sadly, Glock went right back to the vertical with Gen4s. M&P serrations are awesome.

Their narrow width, angled depth and sharper height of slide serration pattern allows racking of slide with less effort.

With Tennifer finish, treated internals: everyone would agree how weather-proof and abuse-capable Glocks are.

M&P pistol above has Cerakote finish on slide and barrel, Robar NP3 finish on magazines. Original finish rusts.

To be thorough, all guns and mags should have emulsifing oil like Ballistol part of the cleaning and relubing task.

Kimber's KimPro finish on Tac Entry and Aegis slides made them very hard to grasp. They're already difficult due to

the width, depth and rounded heights of the slide serrations. Aegis' slide serration pattern is way too wide and

offers no solid grip even when slide is dry. Unacceptable exchange of style for function. Sig P228 slide serrations

were effective even with excellent slick-surfaced NP3 finish, even when this wet in the rain. Unfortunately, Sig P229

models that succeeded the P228 all have half-height serrations that make racking the slide a new frustration when

under any pressure, if hands are wet or simply when one does not get a secure grip of serrations to rack the slide.

Before anyone begins the cliche' comments on how revolvers would be a better choice than semiautos,

here's an array of pictures/facts concerning more fine-motor-skill requirements for revolvers vs semiautos.

NP3 satin gray nickel-teflon finish is now applied by Wright Arrnory: wrightarmory.com

Taurus Judge - why a standard .38 +P revolver may be more sensible

Novel? Yes. Interesting? Yes. Good for snake country and dealing with rodent pests on a ranch? Yes.

Practical and THE answer for what advertisers/sales-pitchers claim too loosely in defense talk? Maybe not.

Still talked-up and talked-about; the Taurus Judge. Many commercial articles and ads claim greatness.

Versatility, defensive revolver prowess, impressive imagery from Taurus' own color advertisements...

Limited reality checks / gullibility by firearms-for-defense purchasers have distracted many from sensibility.

Come on now - would you really depend on such vulnerable wiring and batteries within grip panels?

And only in Hollywood films and darkened smoke-filled rooms do laser beams look so darn good...

First shots and tests with various shotshells at 9 to 10 yards. It's true, the patterns are weak at this distance.

Average amount of muzzle lift firing .410 shotgun loads from Taurus Judge. Target distance 5 to 6 yards.

Federal's Game-Shok .410 #6 shot. Shown on white paper above and below is result of two shells fired.

Taurus' ads look neat but uses bright green Shoot-N-C targets "fired at 6 feet" on their fine print disclaimer.

This load for standard .410 shotguns prints better concentrated patterns than Federal's specialty load below.

Federal's Premium "just-for-Judge .410 Handgun" #4 shot. Sparse pattern. $17 for 20 rounds. (85c/round)

Remember, these tests are conducted at very realistic and likely 5 - 6 yards. You don't want wide-open

patterns like these at such distances. Many say 'it will discourage them...' Ok... want to bet on birdshot

when attacked by a determined, aggressive opponent? - and all you do is pepper them with tiny shot?

What if they have a firearm / blade / impact weapon and close distance with momentum in three strides?

How about .45 Colt? (often called 'long colt') - it does have more muzzle lift, but more convincing power.

CCI .45 Colt 200gr Jacketed Hollow Point, about $50 per box of 50 rounds. ($1 per round)...

For picture-proof answers to "what if?" more .410 birdshot on the target... fired two more on each paper.

Left: 4 shells game load Federal number 6 shot .410 Right: 4 shells 'special' Federal number 4 shot .410

All shot peppered the paper even more, but proof on paper that the 'special' Fed #4 is too sparse a pattern.

Most place-of-sojourn defense distances would be greater than six feet...and even if closer - will you really

feel comfortable in birdshot's claims to 'stop the threat'? I'd choose two to four rounds of .45 Colt instead!

Then for practicality: availability, economy, controllability - .38 special or .38+P - is truly more sensible!

Ruger's winner of a polymer snub-nosed revolver - the LCR

Ruger's lightweight compact revolver is controllable and still lightweight. Here's coverage of what was

discovered in a straightforward test including a rightfully popular counterpart, the Smith & Wesson 642.

The LCR by Ruger is 13.5 ounces, has an aluminum frame around the stainless cylinder and barrel, yet

the grip housing, trigger guard and entire back portion is polymer. Grip has a cushioned web by Hogue.

The 642 by Smith & Wesson is 15 ounces and other than the stainless cylinder and barrel, is traditional

lightweight aluminum. Grip on the S&W 642 has an exposed web backstrap style from Uncle Mike's.

As a quick and non-scientific test, three shooters tried 130gr to 158gr loads from various manufacturers in

the LCR and 642. Results were obvious - both had recoil, but Ruger's LCR had less abrupt muzzle rise and

was clearly easier to control. (Medium framed 4" on right is the proven steel S&W 66. Even more control.)

The polymer frame and air pocket backstrap of Hogue grip on the Ruger LCR added to its control.

Amazing, though not surprising. There will be more firearms moving toward polymer construction.

As an aside, a reminder is due on how much easier it is to eject spent cases from larger revolvers.

With a longer ejector rod on medium (3 to 4" barrel) revolvers, punching fired cases from the cylinder

is more positive than shorter 2" barreled revolvers. There simply isn't enough excursion to the rod.

As new products or advancements go in the world of firearms, most prevalent will prove to be increased

acceptance of polymers - which makes sense. As usual, there'll be many who continue to doubt plastics...

Straightforward comparisons on two modern production 1911s:

Kimber Super Carry Pro and CZ / Dan Wesson Bobtail Valor

While there are never-ending comparisons being made on 1911s or some useless '__vs__' article about

'which defensive handgun/rifle is best' (but then compares firearms that have different operating systems),

the following segment will be a blunt, factual comparison between two 1911s in the same style/category.

Scathing points will also be made on 1911s in general. The truth will upset many.

I too have 1911s, I just don't claim them to be the final answer for everything.

There's a clear winner if comparing the two, winner exemplifing "you get what you pay for."

^ Kimber's 4" barreled full-size aluminum frame offering retails at $1,530. All its key small parts are MIM.

CZ's 4.25" barreled full-size steel frame has a retail of $2,040. All key parts on it are forged, not MIM. ^

Either may be found at some $200 discount, yet at $1,300 and $1,800 one still should recognize differences.

Both are 'worth their respective price bracket' and are 'wonderful 1911s' - but are they 'ultimate' carry guns?

Both are produced with angle-cut 'bobtail' frame that was most commercially popularized by Ed Brown.

Reducing unecessary pointed butt of frame for concealed carry with 1911s, it also reduces perceived recoil.

The Kimber has ambidextrous safety levers, CZ does not. Both have night sights and rear sights are ledged

to provide solid hook for emergency racking of slide. Serrations on both slides are not quite secure if wet.

Blued steel slide of Kimber has rust-resistant coating, stainless steel frame and slide of CZ also has coating.

Here's where it gets blunt - truly blunt. Kimber's frontstrap has a pointless artistic-for-nothing design that

has no worthwhile grip. Look at many production aluminum framed 1911s' frontstraps. They often cheat

using a generous border of no-texture at the area between trigger guard and start of texture/checkering.

CZ Valor has bonafide 25 line-per-inch checkering that provides positive secure grip whether wet or dry.

See it either way you want - I would favor better grip provided by 25 lpi checkering over any fancy design.

Covering up / making safe zone of machine work never beats higher-cut checkering on even pricier 1911s.

Wood looks nice. Fragile, susceptible to everything: impact, prolonged exposure to water/oils/solvents.

G10 (glass woven fabric+epoxy resin binder formed under high pressure) is near-impervious to elements.

All guns with grip panels suffer possibility of loose grip panels/losing grip screws/temptation to buy grips.

Are you kidding me?? The nearly invisible design crap on mainspring housing of Kimber Super Carry Pro

offers zero in indexing or grip for center palm of firing hand. CZ Valor has their proper 25 lpi checkering.

When will gun manufacturers realize defensive fighting guns must have secure grip on frames and slides?

Important small parts: slide stop, thumb safety, hammer, grip safety. Simply put, Metal Injection Molded

parts are cheaper to produce and weaker than billet steel. Unless one experiences serious parts breakages

the majority of consumers won't believe how important it is to spend a little more on such important parts.

I have had several MIM parts break on a few 1911s of mine - two didn't even make the 500 round mark.

Here's a glaring truth: if there is really such a serious need for a concealed carry/'the worst situation' gun -

use simple internal striker-fired handgun like Glock. Costs less, less parts, simpler, easier to teach others.

You wouldn't hesitate to run the gun hard, get it dirty / wet, bash it, beat it up, no grip panels to get loose.

Bushingless bull-barrel design of popular 4" barrel 'Colt Commander emulating' Kimbers look good in ads.

Combined with a full length guide rod, it complicates routine disassembly versus standard short recoil guide.

Must use wire disassembly tool (paper clip can work if you lose yours supplied by Kimber) for such design.

CZ was smart to use proven Colt's Commander design: stick to simple barrel bushing design disassembly;

avoiding full length guide rods that do not improve accuracy or some ridiculous claim that, in the end, has

nothing to do with scoring life-or-death hits that would be decided within a frightening 1-3 paces/seconds.

If taking the compressed recoil spring assembly apart for the Kimber Carry Pro, parts count for both guns

on field-stripping is nearly identical. Both as 1911s have even more tiny parts that would be revealed only

when detail stripping guns' slides and frames. Again, remember that more parts equal more to go wrong.

Also remember range use has nothing to do with operating considerations of every worst case scenario.

Spray Paint Camoflauge

Simple, economical for sure - have fun with it and create your own desired and effective patterns.

Cleaning and degreasing surfaces crucial. Even basic paints can help prevent rust on steel parts.

Base colors are easily fogged and overlapped with straight spraying of selected spray paint colors.

The most simple method to the freckling, blotching, smudging effects is using natural sea sponges.

Random, irregular sea sponge surfaces allow everything from fine digital-like dots to mashed colors.

Cerakote Finishes by Red Letter Industries

[Custom work done locally here on Oahu]

Spray and bake finish, costs more than rebluing or phosphating, but more durable. Can be applied in various colors.

Glock 17 Cerakote Light & Dark Blue Titanium |

S&W MP9 Core Cerakote Desert Sage |

Fullsize MP22 slide, baseplates: Cerakote Purple

|

Compact MP22 slide, baseplates: Cerakote Tiffany Blue

|

Glock 17 slide, baseplates: Cerakote Concrete Gray

|

Glock 17 slide, baseplates: Cerakote Foliage Green

|

Vector Arms Uzi, Glock 19: Cerakote Darkened Burnt Bronze. Uzi barrel+bolt: Cerakote Graphite Black.

FN SCAR 17 .308 rifle, mag and Surefire 3P-762 flashhider: Cerakote Tungsten and Armor Black

Savage Mark II .22 bolt action rifles: Cerakote Ridgeway Blue and Crimson Red

... more projects by Red Letter Industries October 2022

[Custom work done locally here on Oahu]

Striking set of knife, handgun, rifle... time to create a trio of your own!

... more projects by Red Letter Industries October 2022

[Custom work done locally here on Oahu]

Slide and frame laser engraving; texture and depth decided by number of laser passes on material

Laser engraving on slide by Red Letter Industries January 2023

[Custom work done locally here on Oahu]

Laser engraving of frame by Red Letter Industries November 2022

[Custom work done locally here on Oahu]

Laser engraving of KaBar by Red Letter Industries December 2022

Becker BK-18 now actually has some texture

versus factory issued smooth slippery handle

|

[ New release 2023 Becker BK-18 Harpoon ]

Waikiki shoreline - Diamond Head engraving

|

Laser engraving of frame by Red Letter Industries December 2022

[Custom work done locally here on Oahu]

[top half item description]

[Zev Technologies bronze barrel, Raven slide]

|

[top half item description]

[Rival Arms tall tritium sights, Trijicon RMR]

|

Laser engraving of frame detail

Double undercut trigger guard modification.

Starburst pattern angle purposely dissimilar seen front to back circumference of frame. |

Laser engraving of frame detail

|

Robar Coating Technologies Services

Featured: NP3 finish

L: Rain-soaked Sig P228 with NP3 finish. Naysayers of NP3 try and see how quick a Nitron finished Sig will rust.

R: Browning Buckmark would rust horribly if not treated with a good finish. Slide, barrel, rear sight originally blued.

Both guns' magazines would have to be taken apart, dried, cleaned and oiled if they were original factory bluing.

Of course, guns and mags should be cleaned and oiled well after such a soaking. NP3 helps alleviate concerns.

2022: NP3 satin gray nickel-teflon finish is now applied by Wright Arrnory

Cleaning made easier with Robar Technologies' NP3

Rub marks appearing on barrel after firing is easily wiped off. NP3 finish is so slick that fouling cannot adhere.

Locking block, inside of frame: Carbon fouling wipes right off. NP3'd barrel exterior, recoil spring guide too.

Inside of barrel is not NP3'd, so clean it as usual with bore brush, solvent, oil, etc.

Slide breechface and under extractor: A nylon brush does it and that's without any harsh solvents or liquids!

Clean under the extractor, and once that is done the rest is an easy wipe-down. Clean under the extractor, and once that is done the rest is an easy wipe-down.

Within slide recesses, cleaning can be with paper towels; without harsh solvents. Light oiling and it's done.

NP3 coated Auto Ordnance Thompson: bolt assembly and inside of reciever after 400 rounds were fired.

Cleaning promptly yields an easier time at it, again most of the carbon fouling is wiped off with paper towels!

Sig 556R 7.62x39 overview and testing

First Sig 556R 7.62x39 tested was version with railed handguard, shown with a Leupold 1-4x VXI.

Red dot sight (Chinese copy of an Aimpoint H1/T1) that they come shipped with - is not exciting.

Good scope setup? A compact Leupold in QRW rings is a quality cost-effective solution (~$300).

Folding sights must be lower height such as Troy Micro Sights to accommodate lower cheekweld.

All 556Rs (and the .223/5.56 models) have ambi safeties and reciprocating charging handles.

Thankfully, charging handle a good distance away from thumb of right hand when it is a support hand.

Immediate note about this version of 556R: very heavy versus the standard plastic handguard version.

And, 556Rs will not accept all AK mag varieties. They come with 1 Tapco mag, and steel mags work.

Varieties of AK mags including excellent US Palm mags will not lock into 556R. Steel mags still the best.

Also, the otherwise awesome Bulgarian 'Circle10' mags have not been locking into the two test 556Rs.

Front and rear catch contour/dimension due to epoxy-like paint and/or plastic layer causes inconsistencies

with 556R's more precise-dimensioned magwell opening; thus very few Circle10 mags locked into place

with any normal effort. Magazines that had difficulties did not give any hard time with eight other AKs.

Modifying two mags yielded slight improvement to insertion effort but I wouldn't want to modify mags

or be concerned about the 'what if I had to grab this or that mag in an emergency and oh no! it don't fit!'

No one should have to press the latch to insert and lock magazine into place to load the rifle, but

that's what had to be done with 9 out of 14 Circle10 mags in this test. Only 5 worked "normally".

Regardless, the Sig 556R rifle has solid shooting capability and as always, just be aware of your

chosen rifle's abilities or quirks. Obviously, magazines for semiautos are a very important concern.

First stages of testing include optic use (low magnification like compact 3x ACOGs and 1-4x Leupolds)

and quickly remind us that proper cheekweld and thus better hits will require correct height optic mounts.

Sept 30, 2012: The railed handguard 556R brought out to range, straight out of this Sig's cardboard box

without pre-cleaning or lube of internals, 150+ steel cased rounds fired by 10 shooters, zero malfunctions.

Horrible fails of early release 556Rs had been corrected it seems, and now confidence in rifle is possible.

This initial firing began rifle's 'break-in period' and noted left-and-right use and shouldering ergonomics.

Close-range 15 yard group consistency was as expected; punching cloverleaf groups with Leupold at 2x.

These steel index tabs for railed aluminum handguard got very hot firing a constant 20~30 rounds and

naturally, transfer heat across the entire handguard. Before many quickly state the solution is to install

vertical/angled grips, don't forget intrinsic facts of mag arc requirements of insertion or extraction and

expect that fighting situations will require different holds of rifle forend in uncommon firing positions.

Magazine's forward catch location is a steel insert within an aluminum lower receiver.

Various countries' steel AK mags and Sig's one issued Tapco mag worked flawlessly.

Oct 7, 2012: Tests continue with the railed handguard Sig 556R at 100 yards on paper utilizing

Burris 3-9x40 BallistiPlex scope in Larue SPR mount. Remington 7.62x39 FMJ was amazing.

'Can't-complain low-priced' Tula and Golden Tiger didn't shoot near as consistent as expected.

How S&B's soft point load dispersed crazily is shocking. Could it be related to bullet diameter

for particular loads versus the inside diameter of bore? This is why most American manufacture

7.62x39 bullets miked at .308 diameter printed better out of Ruger Mini Thirty rifles with .308

bore diameters versus running foreign ammo that miked at .310 diameter. 556R has .310 bore.

That should eliminate questions about bullet outer versus bore inside diameter, and focus on powder type/

loading consistencies. Groups fired for score or testing just need to be done on best days and conditions.

Hits on distant 450 yard steel (thru-scope image down below) was good using Burris Ballisticplex reticle.

Oct 14, 2012: Testing continued with a second 556R that had a standard plastic handguard.

Similar results with previous manufacturer's ammo; even more was tried as 'off-the-shelf test'

continued in the thought process of 'what if you had to grab one of these right now and use it'.

This rifle also had no oiling or pre-firing cleaning done to it. This kind of testing is solid realism.

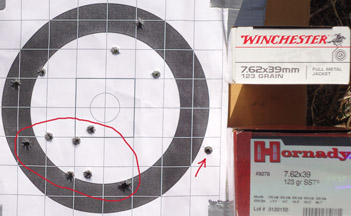

100 yards: after adjustment from first shot at arrow, Hornady SST 7.62x39 was rather good. Winchester was

dismal in the upper half of aiming circle. Combined result of budget Golden Tiger and Tula was as expected.

As usual, better quality ammunition will give better results. View thru Burris scope with Ballisticplex reticle.

450 yard distant steel rectangular plate in shadow and partially obscured in lower thick vertical crosshair

is already tough to hit even with a quality Arsenal AK fitted with Texas Weapons top cover and scope -

but either Sig 556R (standard plastic or railed handguard version) had more frequent hit results on steel.

7.62x39mm drops severely after 300 yards; hitting requires consistent ammo and careful trigger control.

Even with the increased abilities of Sig 556Rs over high level AKs, the market absence of the 556R and

occasional problems of that rifle put it right back to a questionable category instead of a resounding yes.

However, after procuring quality optics, weeding thru mags then testing Sig 556Rs with US and non-US

manufactured ammo, it is clear that spending all the money and time to work on such projects just doesn't

yield results that can be achieved much easier and with far less cost and fanfare with virtually any AR15... Ammunition advancements in .223/5.56, prudent maintenance of one's choice in fighting rifles and honest

progressive training will produce same venerable results without requiring costly equipment diversions.

Continuing report on Vector AK-47

September 20, 2005

Ongoing 'test' continued over three months. It will continue as long as I can resist cleaning this AK...

Vector Arms Model AUSA, at the 300 round mark. Of course, we all "know" AKs can handle abuse; just conducting a long term test to see how much crud it can take and how Vector's parkerized exterior holds up.

Earlier reports looked at different magazines and feeding characteristics. There are differences. Due to vast

numbers and varieties of AK rifles out there, some magazines may not work well in one AK as another.

Underside of the reciever magazine well opening, some accumulation of crud. Stamped mfg: Armory USA.

Recievers, mag well openings, mag catches will be different. Some Romanian WASRs had difficulties with

insertion/extraction of mags due to being converted (widened mag openings) from single stack configuration.

At first stage of AK disassembly; carbon is seen on the recoil spring guide where it goes into the bolt carrier.

Looking inside the reciever, not much particles or fouling, this is around 400 rounds. I doubt it looked any

different at the 300 round mark. AK design allows less firing residue to find their way into the reciever.

Some rust visible in gas block. Background: the normally bright gas piston is black, covered with carbon.

L to R: Front view of recoil spring guide and captured spring, gas piston, gas piston tube, bolt assembly.

Inside slant brake is expected carbon build-up. Time to fire more rounds! Next report around 600 rounds.

750 rounds

December 10, 2005

Same AK continues to be fired when there is enough time to shoot at least 100 to 200 rounds at a session;

here are pictures of the AK after being handled and fired at last month's HRA fun shoot without being

wiped down on exterior (and it will continue to be neglected with no cleaning of the bore or interior).

Rust has started on parkerizing - on areas frequently touched like the safety lever, surrounding top cover,

bolt handle, mag catch lever, and naturally more fouling built up in magazine well and chamber of rifle.

Some rust started on trigger and top of mag has obvious wear marks. For firearms like AKs and variants

without bolt hold-open devices, use something in ejection port (empty 12 gauge hull shown here) showing

chamber is empty during cease fire on firing line. Don't rely on temporary 'hang' of the bolt to the rear.

Developments since the last 400 round report: rear sight leaf is stuck at the battle setting and the

upper handguard is still loose (wobbles a little left and right) but who cares? The AK still works!

Many types of 7.62x39 ammunition continue to be fed into the rifle. By the way, all five types shown seemed

to hit the steel plate at 450 yards with regularity while utilizing the same sight picture and slight 'holdover'.

Soft point ammo (center box) made a different sound when striking steel. The hollow point fed just fine.

(L) Shown for clarity: "entire front sight" sight picture, (R) worked for distance of approximately 450 yds.

This is with rear sight leaf set at the battle setting (without moving it to the 400 mark) as it is stuck there.

In the (L) picture, you can just make out the steel plate (a greyish dot) right above the front sight post.

Accepted is the fact that left-right windage is set and mechanically zeroed slightly off-center as seen here.

(R) picture: background and target area is depicted correctly 'out of focus' as we focus on the front sight.

the firing continues . . .

1100 rounds

March 26, 2006

We know AKs as well as other military firearms are supposed to take being in the rain or be submerged -

How about actually doing it?!?

The best day yet - a fun shoot where it had been raining for weeks with resultant ponding of water . . .

To start off, rounds continued to be fired and the AK left in the rain for March HRA fun shoot.

Get ready for the plunge:

and into the pond of water it goes! The cheers and groans from other shooters present were awesome.

This is the beginning of the 'real deal' - and it sure does look at home doesn't it?

Let it sit for a minute, then extract...

let water out of the barrel (the gas tube design has more drainage clearance for sure),

and of course, it fires perfectly fine. Weeks ahead, we will see how interior holds out. For sensible care

of rifle, I dried off water inside and out to make sure rust over the next series of months does not cause

any parts malfunctions or failures. This would be utilized for more sessions of shooting as well as be

featured at July Shooting Sports Fair. Exterior metal was oiled to prevent rust transferring to clothing.

Most people would appreciate not having rust brown get on their clothing when having fun shooting.

1900 rounds

July 8, 2007

600+ rounds fired during '06 and '07 Shooting Sports Fair contributed to 1900+ rounds to this date ....

Continuous report tests functioning of an abused and occasionally fired AK without cleaning 2 years ....

Even better: foreign crud in the action firing test. Disclaimer: do not recreate this test. Be prepared

for stoppages. Yes, with enough grass, dirt and rocks in the action ANY gun will have stoppages.

Wonderful part of this: the vast space inside the action of an AK allows it to throw and crush

most of the crud. When it fails to feed and close bolt fully, a strong rack of the bolt handle and

simultaneous tilt to the right clears stoppages, chambering next round and firing could continue.

2200+ rounds

December 23, 2007

Here is the final segment of the AK long-term torture test; more than two years since starting in June 2005

and tracked with a diary in pictures since September 2005. The final hurrah was a bowling pin shoot with

some ferocious firing against some not so ferocious pins (yet must be taken out nontheless!) - fun for sure.

A week after the fun, another session of firing. Now the complete disassembly of the trusty Vector AK:

Lots of caked-on carbon and crud on the bolt carrier and bolt assembly.

Almost a full two and half years of intermittent firing, round count now just over 2200 rounds.

While this long-term test did not have a high round count (like 10,000 rounds or so), the testing was to

prolong firing and cleaning of an AK over an extended period of time so carbon and crud could accumulate.

No one should abuse their AK or any firearm as depicted here, especially when cleaning time and supplies

are available in some form or another; and because "we should not conduct this gross abuse of a firearm....."

Disassembly tips for an AK - including gas tube and lower handguard

Vital disassembly procedure: Remove the source, check chamber, and check again.

Press guide rod button on rear of reciever to release top cover, remove recoil guide assembly.

Remove bolt carrier assembly - retract fully to rear, lift out at rearmost position.

Gas tube upper handguard's release lever can be rotated

with a crescent wrench or original slotted AK tool.

Approximate position of release lever to allow upper handguard to be lifted up and out.

Remove AK cleaning rod if it's on your rifle. Some AKs may not have them.

Lower handguard's front retainer has 'L' pin to be rotated forward. Masking tape helps prevent tool marks.

Plastic mallet taps retaining cap forward, groove where the 'L' pin would be turned and locked down.

Lower handguard tips down. Here's a nice surprise: a wood forend with metal tensioners for retainer cap.

Now the gas tube (upper handguard assembly), gas port, lower handguard assembly and barrel's exterior

can be cleaned and oiled as desired as well. Also, any handguard replacement project can be performed.

|